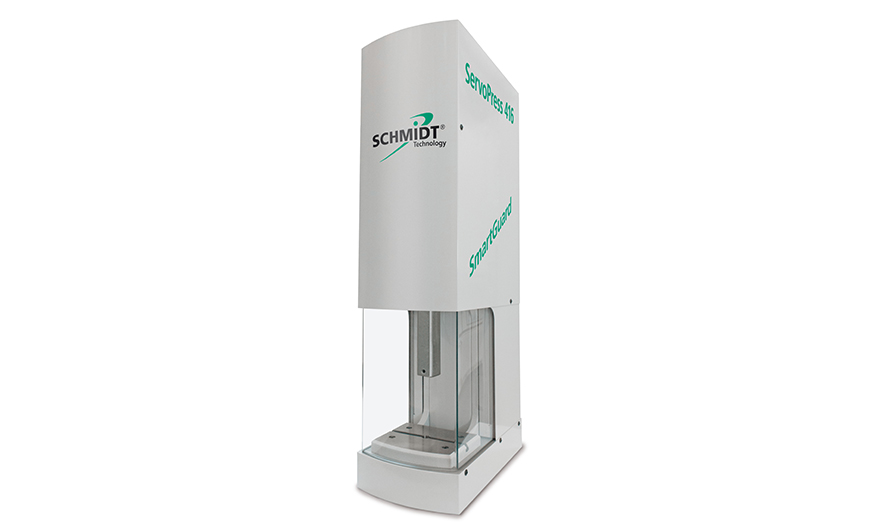

During the development of the compact guarding SCHMIDT® SmartGuard, the focus was on ergonomics and protection at the workstation. The transparent guarding completely encloses the working area during the pressing process, effectively protecting the operator and third parties from reaching into the danger zone and from any ejected parts or splinters. Thanks to minimised distances to the work area, workstation can be significantly improved in terms of ergonomics and efficiency. The high dynamics of the NC-controlled protective bonnet and its variable positioning and stroke speed optimise the work cycle. The danger of crushing in the closing protective bonnet is eliminated by the clever design.

Related Posts

SCHMIDT DuplexPress 8

SCHMIDT® DuplexPress 8 DuplexPress 8 hand lever press with mechanical press force reinforcement through planetary gears A new

Read More 0 SCHMIDT ElectricPress 347 with 20 kN

SCHMIDT® ElectricPress 347 with 20 kN max. force The brand new extension of our ElectricPress series with the

Read More 0 Laminar flow monitoring – reliable and robust – even with intensive cleaning processes and the use of aggressive media in pharmaceutical plants

Laminar flow monitoring – reliable and robust – even with intensive cleaning processes and use of aggressive media

Read More 0 Flow Sensor SS 20.700 for heavy-duty applications in air and other gases

Flow measurement in harsh conditions The SCHMIDT® flow sensor SS 20.700 is a robust solution for highly demanding

Read More 0 Duplex flow sensor SS 20.415 redundant laminar flow monitoring

Redundant laminar flow monitoring at one measuring point SCHMIDT® duplex flow sensor SS 20.415 Twin* is a high-precision

Read More 0 New EU-Type Examination Norm

New EU-Type Examination Norm. The new Machine Tool Safety line of norms DIN EN ISO 16092 came into

Read More 0 CamPress 11N

SCHMIDT® CamPress 11N The best of both worlds We have merged the best of the two types of

Read More 0 This is what winners look like: 3rd place at the Handling Award

This is what winners look like! Our mechanical development manager Andreas Meyer and the entire SCHMIDT Technology team

Read More 0 Verify flow sensors on site

Installed flow sensors should be verified on site from time to time, especially in clean rooms or in

Read More 0 Read out flow data even easier

SCHMIDT® smart solutions with Bluetooth® technology – wireless flow sensor values are transmitted anytime and anywhere In many

Read More 0