SCHMIDT® ServoPress

Forces from 0.3 kN to 250 kN

High-quality yet economical assembly is the guarantee for product success on the market. The goal is to join precise assemblies from inexpensive individual components with tolerances. Electrically driven screw presses – servo presses – are ideally suited for such tasks in terms of precision. In addition, the modules are characterised by high dynamics over the entire force and stroke range as well as excellent repeat accuracy.

The ServoPress systems offer the perfect solution in the interaction of ServoPress modules and the PressControl 700 or PressControl 7000 controllers developed for this purpose. These meet the most complex requirements, in single workstations as well as in fully automated production lines.

The full-load modules of the SCHMIDT® ServoPress series are EC type-approved in combination with the safety technology options SmartGate, SmartGuard and light curtain. Furthermore, the servo presses have an integrated automatic spindle lubrication system and are protected by an overload clutch from type 616.

SCHMIDT® ServoPress 602 is ideal for use in the smaller force range with high demands on precision, e.g. in the following branches of industry:

Medical technology

- Assembly of hearing devices and implants

- Assembly of cardiac pacemaker

Watch industry

- Assembly of axle and gear

- Setting of gemstone bearings

Micromechanics

- Assembly of small electric motors

- Assembly of miniature gears

0.3 kN force F max. S3 25 %, 20 sec

0.2 kN force F 100 % ED

75 mm ram stroke

0 – 150 mm/s speed max.

±1 µm/inc resolution measurement data acquisition – way

0.4 N/inc resolution measurement data acquisition – force

0,1 µm resolution position control

SCHMIDT® ServoPress 605 is ideal for use in the smaller force range, e.g. in the following branches of industry:

Data communication

- Assembly of network connectors

- Assembly of high-frequency connectors

Electronics

- Component assembly on circuit boards (e.g. Compliant Pin)

- Switch assembly, plug assembly

Automotive safety technology

- Assembly of airbag sensors

- Assembly of distance sensors

1.0 kN force F max. S3 25 %, 20 sec

0.5 kN force F 100 % ED

150 mm ram stroke

0 – 300 mm/s speed max.

0.1 µm resolution position control

2.2 μm/inc resolution measurement data acquisition – way

0.3 N/inc resolution measurement data acquisition – force

SCHMIDT® ServoPress 616 for use in the small to medium force range, e.g. in the following branches of industry:

Automotive

- Valve assembly

- Complete assembly of assistance systems

Electronics, electrical engineering

- Assembly of power modules (Compliant Pin)

- Fan assembly

Precision technology

- Bearing assembly

- Lens assembly for optical sensors

5 kN force F max. S3 25 %, 20 sec

3 kN force F 100 % ED

200 mm ram stroke

200 mm/s speed max.

0.1 µm resolution position control

3.2 μm/inc resolution measurement data acquisition – way

1.5 N/inc resolution measurement data acquisition – force

SCHMIDT® ServoPress 617 for use in the medium force range, e.g. in the following branches of industry:

Automotive

- Assembly of injection systems

- Fitting assembly

House and building technology

- Installation of meter systems

- Assembly of pump systems

Medical technology, pharmacy

- Straightening / shaping surgical instruments

- Cutting pharmaceutical filters

14 kN force F max. S3 25 %, 20 sec

7.5 kN force F 100 % ED

300 mm ram stroke

200 mm/s speed max.

0.1 µm resolution position control

4.6 μm/inc resolution measurement data acquisition – way

3.75 N/inc resolution measurement data acquisition – force

SCHMIDT® ServoPress 620 for use in the higher force range, e.g. in the following branches of industry:

Automotive

- Assembly of catalyst monoliths

- Assembly of shift gate

Optics

- Setting glass lenses in eyepieces

Medical technology / pharmacy

- Calibrating / straightening artificial joints

- Compaction of medicinal granules

35 kN force F max. S3 25 %, 20 sec

20 kN force F 100 % ED

400 mm ram stroke

200 mm/s speed max.

0.1 µm resolution position control

6.1 μm/inc resolution measurement data acquisition – way

10 N/inc resolution measurement data acquisition – force

SCHMIDT® ServoPress 660 with integrated energy management and intermediate storage of braking energy for use in the high power range, e.g. in the following industries:

Electro mobility

- Crimping cable lugs

- Moulding of battery packs

Aeronautics

- Moulding of stringers (aluminium profiles)

75 kN force F max. S3 25 %, 20 sec

50 kN force F 100 % ED

500 mm ram stroke

200 mm/s speed max.

0.1 µm resolution position control

7.6 μm/inc resolution measurement data acquisition – way

24 N/inc resolution measurement data acquisition – force

SCHMIDT® ServoPress 655 with integrated energy management and temporary storage of braking energy. For use in the high force range, e.g. in the branches of industry:

Drive technology

- Caulking bearing rings

- Transmission assembly

Electrical engineering

- Mounting bolts in grounding rails

House technology

- Installation of heating pumps

110 kN force F max. S3 25 %, 20 sec

80 kN force F 100 % ED

500 mm ram stroke

100 mm/s speed max.

0.1 µm resolution position control

7.6 μm/inc resolution measurement data acquisition – way

32 N/inc resolution measurement data acquisition – force

SCHMIDT® ServoPress 660 with integrated energy management and intermediate storage of braking energy for use in the high power range, e.g. in the following industries:

Electro mobility

- Crimping cable lugs

- Moulding of battery packs

Aeronautics

- Moulding of stringers (aluminium profiles)

160 kN force F max. S3 25 %, 20 sec

110 kN force F 100 % ED

350 mm ram stroke

100 mm/s speed max.

0.1 µm resolution position control

5.4 μm/inc resolution measurement data acquisition – way

48 N/inc resolution measurement data acquisition – force

SCHMIDT® ServoPress 680 with integrated energy management and temporary storage of braking energy for use in the peak force range, e.g. in the following branches of industry:

E-mobility

- Ground strap crimping

- Crimping high-voltage cables

Automotive

- Shaping / calibrating components made of sintered metal

250 kN force F max. S3 25 %, 20 sec

200 kN force F 100 % ED

350 mm ram stroke

50 mm/s speed max.

0.1 µm resolution position control

5.4 μm/inc resolution measurement data acquisition – way

75 N/inc resolution measurement data acquisition – force

| Press type | 605 | 616 | 617 | 620 | 650 | 655 | 660 | 680 | |

|---|---|---|---|---|---|---|---|---|---|

| Force F max. S3 25%, 20 sec | kN | 1.0 | 5 | 14 | 35 | 75 | 110 | 160 | 250 |

| Force F 100% ED | kN | 0.5 | 3 | 7.5 | 20 | 50 | 80 | 110 | 200 |

| Ram stroke | mm | 150 | 200 | 300 | 400 | 500 | 500 | 350 | 350 |

| Speed max. | mm / s | 300 | 200 | 200 | 200 | 200 | 100 | 100 | 50 |

| Position control resolution | µm | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Resolution measurement data acquisition – force | N / inc | 0.3 | 1.5 | 3.75 | 10 | 24 | 32 | 48 | 75 |

| Resolution measurement data acquisition – distance | μm / inc | 2.2 | 3.2 | 4,6 | 6.1 | 7.6 | 7.6 | 5.4 | 5.4 |

| Projection | mm | 130 | 130 | 150 | 160 | 160 | 160 | 160 | 160 |

| Dimensions press module H / W / T | mm | 636/89 / 155 | 599/124/258 | 892/144/318 | 1077/190/384 | 1250/243/561 | 1250/243/561 | 1249/249/552 | 1249/249/552 |

| Weight press module | kg | 11.6 | 25 | 64 | 113 | 225 | 225 | 283 | 283 |

| max. Tool weight | kg | ≤ 5 | ≤ 15 | ≤ 25 | ≤ 50 | ≤ 100 | ≤ 100 | ≤ 100 | ≤ 100 |

| Ram bore | mm | 6H7 | 10H7 | 20H7 | 20H7 | 20H7 | 20H7 | 20H7 | 20H7 |

| Dimensions of the ram | mm | Ø 25 | Ø 40 | □ 42 | □ 55 | □ 65 | □ 65 | Ø 90 | Ø 90 |

Characteristics

Real-time evaluation

- immediate reaction to process and quality data

- no delay due to slow process data transfer

- Immediate availability of SPC data.

System immediately operational

- Standard travel profiles only require the entry of position and speed

- The system parameterizes itself automatically.

Precise and robust mechanical structure

Precise and robust mechanical structure

Process control behavior

- Distance measurement directly on the ram, resulting in extremely high positioning and repeat accuracy

- Absolute position measuring system, therefore no reference travel necessary

Intelligent compensation

- by offsetting individual tolerances of the parts

- of system elasticities (deflection compensation)

Accessories ServoPress

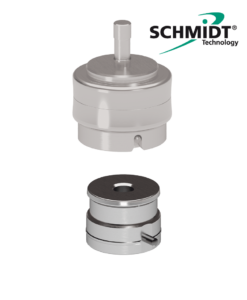

Upper tooling adapter

Adapter for tools with a diameter of 5 – 20 mm.

Quick Coupler for tools

consists of two parts: a rigid adapter and a base holder for mounting in the ram.

SCHMIDT® Press Base (PU)

Provides safe and vibration-free installation of all presses.

SCHMIDT® Slide Tables

Position longitudinally as well as transversely with high accuracy.

External handwheel

for intuitive setup of operating profiles

Safety concepts with EC type examination

SCHMIDT® SmartGuard

Patented safety with a slim design, fast component feeding, protection against intervention as well as splinter protection from chipping of parts.

SCHMIDT® SmartGate

Patented safety with freely programmable safety gates for large presses, fast component feed, protection against interference as well as against parts flying out.

Light Curtain

In the event of unauthorized interference, the pressing process stops automatically.

SCHMIDT Presses product catalog

Find out everything about the various functions of our presses.

download PDF