Laminar flow monitoring - reliable and robust - even with intensive cleaning processes and use of aggressive media in pharmaceutical plants

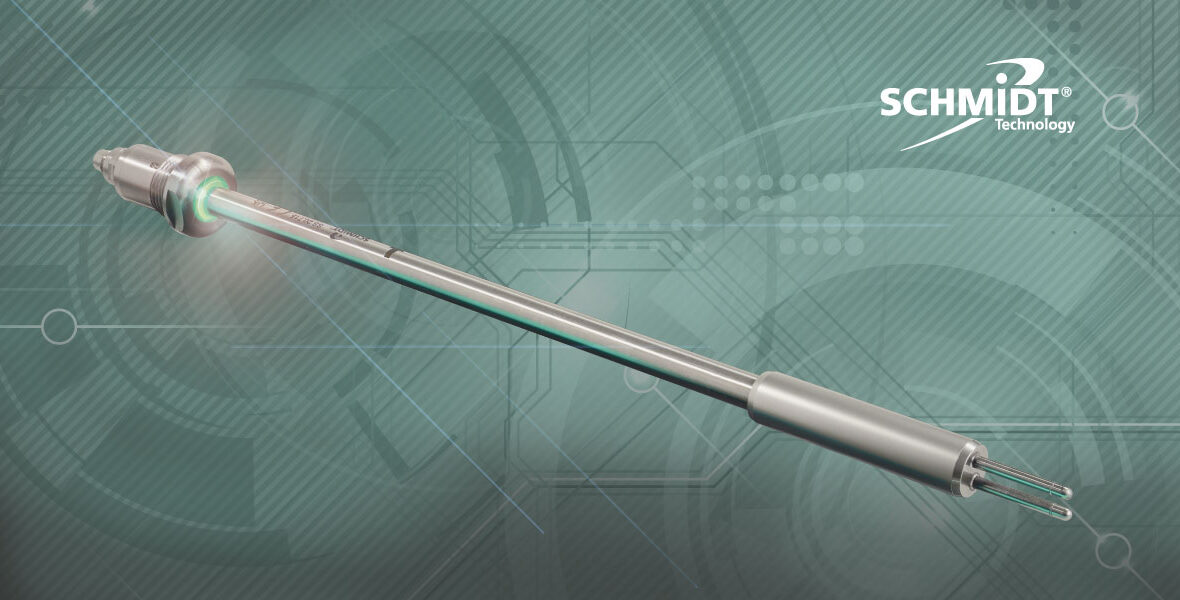

Introducing the SCHMIDT® Flow Sensor SS 20.715 LED, a robust solution for continuous monitoring of laminar airflow in clean rooms and clean applications. With sensor elements completely encapsulated in stainless steel, it impresses with its resistance to aggressive media and dirt and also offers very good protection during the rough cleaning of pharmaceutical systems.

Monitoring the flow in cleanrooms and clean areas

A direction-defined air flow in clean rooms protects products from contamination and disruptive particles are safely removed. For this purpose, a uniform air flow from the ceiling to the floor is maintained in clean rooms with high cleanliness classes ("directed, low-turbulence displacement flow"; monitoring range from wN = 0.36 to 0.54 m/s). The measurement is carried out on the clean room side after the terminal filters. Since the air circulation is throttled during idle times, high-precision measurement of the air speed from 0.1 m/s is necessary.

The solution: measuring the supply air flow with the SCHMIDT® flow sensor SS 20.715 LED

According to the EN ISO 14644-3 standard, the air speed is measured at a distance of around 150 to 300 mm below the front surface of the filter. For easy installation in ceiling and wall systems, the thermal SCHMIDT® flow sensor SS 20.715 LED offers a cleanroom-compatible quick mounting system. The sensor is extremely compact, as all the electronics are built into the sensor tube and therefore no turbulence is generated in the low-turbulence displacement flow.

Individually adapted to each application

There are 3 standard variants to choose from for optimal installation in different applications. The laminar flow sensor can be mounted on the wall in a straight version with a sensor length of 300 mm or in an angled form under the ceiling of the clean room or the bottling plant. The angled design can be configured with the dimensions 270 x 300 mm or 150 x 300 mm (where the first dimension defines the distance to the ceiling; plus mounting system).

Robust solution for pure applications with aggressive media or intensive cleaning

The thermal SCHMIDT® flow sensor SS 20.715 LED is the robust solution for extremely challenging clean room applications. Product changes in pharmaceutical filling plants or simply internal requirements force operators of clean rooms and plants in clean areas to clean them regularly. If aggressive media are used or if more intensive cleaning is required due to significant or very stubborn dirt, the new laminar flow flow sensor SS 20.715 LED with double pin sensor head made of stainless steel is the first choice. The double pin sensor was designed precisely for the aforementioned needs and is ideally suited for demanding applications thanks to the sensor elements completely encapsulated in stainless steel. In addition to the flow rate, the SS 20.715 LED also records the medium temperature from -20 °C to +70 °C. Thanks to the SCHMIDT® quick mounting system, which is suitable for clean rooms, the SS 20.715 LED can be exchanged for an existing sensor without any additional effort and installed as easily as usual. The sensor works without moving parts and due to the measuring principle, drift or aging are irrelevant. Due to the sensor elements being completely encapsulated in stainless steel, the maintenance of the sensor is reduced to an absolute minimum. However, should cleaning be necessary, this can be carried out very easily and in a variety of ways.

High accuracy and detection of the smallest currents

The special double-pin sensor head records flow velocities from 0.1 m/s up to 10 m/s in three selectable measuring ranges (1 / 2.5 / 10 m/s). In order to obtain precise measurement results in this speed range, each sensor is individually adjusted and calibrated in a high-quality wind tunnel. On request, the sensor can also be supplied with a DAkkS-accredited calibration.

Highlights of the SCHMIDT® flow sensor SS 20.715 LED: For laminar flow applications with aggressive components or intensive cleaning processes

Sensor elements completely encapsulated in stainless steel enable extremely easy cleaning

Very robust and extremely compact design (electronics integrated in the sensor tube)

3 sensor length variants: straight design: 300 mm

angled design: 150 or 270 x 300 mm Measuring ranges 0 … 1 / 2.5 / 10 m/s

Temperature measurement range from -20 to +70 °C

Linear analog output for measured value output

Integrated sensor self-monitoring with error signaling

Operating status display and serial number of the sensor visible on the sensor when installed

Special version for laminar flow monitoring in clean rooms with quick assembly technology for easy installation in clean room ceiling and clean room wall systems

DAkkS-accredited calibration (optional) SCHMIDT® Flow sensor SS 20.715 LED: Especially designed for laminar flow applications with intensive cleaning processes: Thanks to the sensor elements completely encapsulated in stainless steel, they are ideal for demanding applications in clean rooms and in clean processes suitable and resistant to aggressive media.