Features

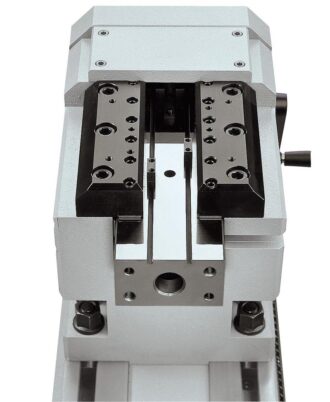

- Easy and accurate positioning of tools due to the precise alignment between ram bore and the ground fixture mounting plate.

* The force output preselector allows reducing the pressure for the power stroke to 1 bar. This reduces the nominal press force to 1 / 6 of the maximum force.

* The end positions of the ram can be sensed via the inductive proximity switches.

* No mechanical compression spring in the cylinder of the hydro-pneumatic system, providing a long service life

* Low maintenance resulting in high productivity

* Long service life and precision due to maintenance-free guides

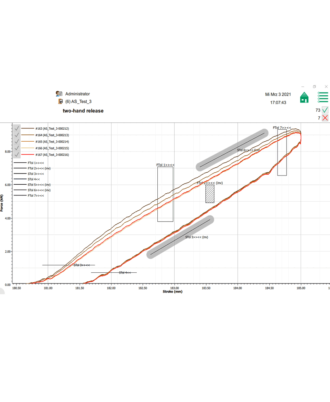

* Tool protection due to smooth switchover from rapid approach stroke to power stroke

* Additional safety when using heavy tools due to the optional ram drift lock device for retention of ram in home position.

* Low noise level (< 75 dBA)