SCHMIDT® HydroPneumaticPress

Maximum press force from 15 kN to 220 kN

The SCHMIDT® HydroPneumaticPress product family is a modular system that optimally meets the requirements of the areas of forming, joining and assembly in the press force range of 15 – 220 kN.

In combination with the SCHMIDT® PressControl 75 or 700 controller, the presses become EC type-tested, CE-compliant workstations, optionally with process monitoring. The press systems can be used in single cycle as well as in automatic mode.

SCHMIDT® HydroPneumaticPress

15 to 100 kN

SCHMIDT® HydroPneumaticPress in H-frame design

with and without force / stroke monitoring

Characteristics

- Optimal adaptation to individual requirements through modular structure.

- High flexibility and economy thanks to the shortest changeover times

- Simple and precise positioning of tools thanks to the centric fitting bore and, in some cases, a cross bore with a locking screw in the ground press table.

- Press force preselection enables the pressure for the power stroke to be reduced to 1 bar. This reduces the nominal pressing force to 1/6 of the maximum force.

- End positions of the ram can be queried via inductive proximity switches

- Long service life, even at high stroke frequencies, thanks to the hydropneumatic system without a spiral spring in the cylinder

- Low maintenance, therefore high availability

- Durable and precise thanks to maintenance-free bearings

- Gentle on the tool – switch from rapid stroke to power stroke

- Additional accident protection when using heavy tools thanks to the ram lifting device on the pneumatic control block (partly optional)

- Low noise level (<75 dBA)

Accessories HydroPneumaticPress

Throat extension block

Press frames and cast parts are electroless nickel-plated, steel components are black oxide finished, aluminum parts are anodized, precision steel surfaces are untreated.

Special fixture mounting plate

Special fixture tabletops, designed in conjunction with throat extension blocks, provide ram to table bore alignment when spacer is used.

Upper tooling adapter

Adapter for tools with a diameter of 5 – 20 mm.

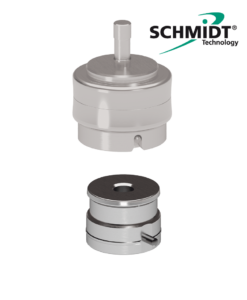

Quick Coupler for tools

consists of two parts: a rigid adapter and a base holder for mounting in the ram.

SCHMIDT® Press Base (PU)

Provides safe and vibration-free installation of all presses.

SCHMIDT® Slide Tables

Position longitudinally as well as transversely with high accuracy.

Special fixture mounting plate

Special fixture tabletops, designed in conjunction with throat extension blocks, provide ram to table bore alignment when spacer is used.

Safety concepts with EC type examination

Two-hand release

Simple triggering by means of two buttons to be pressed at the same time.

SCHMIDT® SmartGate

Patented safety with freely programmable safety gates for large presses, fast component feed, protection against interference as well as against parts flying out.

Light Curtain

In the event of unauthorized interference, the pressing process stops automatically.

SCHMIDT® Presses product catalog

Find out everything about the various functions of our presses.

download PDF