SCHMIDT® ElectricPress

Electric press with high energy efficiency in assembly technology

The use of electric drives instead of pneumatic or hydropneumatic driven cylinders is a modern advancement in assembly technology. SCHMIDT Technology combined its proven rack & pinion and ServoPress experience to create a new electric drive technology, providing high efficiency, full programmability and precision in a flexible pressing system.

SCHMIDT® ElectricPress 43, without force-displacement monitoring, is the alternative to pneumatic presses for use in the small to medium force range, e.g. in the industrial branches:

Automobile construction / motor vehicle

- Ignition key assembly

- Lock assembly

Electronics, electrical engineering

- Mounting of spacer bolts in the circuit board

- Assembly of cable / cable lug

Textile and leather

- Beading ring eyelets in leather straps

- Punching / cutting of textile contours

4 kN force FS3 25 % 10 sec.

2.5 kN force F 100 % ED

100 mm ram stroke

≤ 1 µm resolution drive control

200 mm/s ram speed (max.)

SCHMIDT® ElectricPress 343 in combination with SCHMIDT® PressControl 700 becomes a force-displacement monitoring press system, e.g. in the following industries

Automotive / safety engineering

- Assembly of radar distance sensors

- Assembly of airbag control sensors

Watches / Jewellery

- Assembly of bracelet links

- Setting / beading of rhinestones

Computer technology

- Pressing pins into hard disk housings

- HDD housing assembly

4 kN force FS3 25 % 10 sec.

2.5 kN force F 100 % ED

100 mm ram stroke

≤ 1 µm resolution drive control

200 mm/s ram speed (max.)

SCHMIDT® ElectricPress 45, without force-displacement Monitoring, the alternative to pneumatic presses for use in the medium force range, e.g. in the branches of industry:

Automotive industry

- Flanging lampholder sockets

- Compression of ceramic granules for spark plugs

White goods

- Bending chassis braces

- Embossing nameplates

Motorcycle

- Mounting bearing in aluminum rim

- Assembly of motor housing

10 kN force FS3 25 % 10 sec.

6 kN force F 100 % ED

150 mm ram stroke

≤ 1 µm resolution drive control

200 mm/s ram speed (max.)

SCHMIDT® ElectricPress 345 is used in combination with the SCHMIDT® PressControl 700 for the force-displacement-monitoring press system, e.g. in industries

E-mobility

- Gearbox assembly for e-bikes

- Assembly of battery cores

Medical technology

- Riveting surgical scissors

- Assembly of dental instruments

Drive technology

- Rotor-stator assembly

- Gear-axle assembly

10 kN force FS3 25 % 10 sec.

6 kN force F 100 % ED

150 mm ram stroke

≤ 1 µm resolution drive control

200 mm/s ram speed (max.)

SCHMIDT® ElectricPress 347 is used in combination with the SCHMIDT® PressControl 700 for the force-displacement monitoring press system, e.g. in the branches of industry

Automotive

- Assembly of injection systems

- Fitting assembly

Home and building technology

- Installation of meter systems

- Assembly of pump systems

Optics

- Mounting glass lenses in eyepieces

Medical technology, pharmacy

- Straightening / shaping of surgical instruments

- Cutting pharmaceutical filters

20 kN force FS3 25 % 10 sec.

13 kN force F 100 % ED

150 mm ram stroke

≤ 1 µm resolution drive control

100 mm/s ram speed (max.)

| Press type | 43 | 343 | 45 | 345 | 347 |

|---|---|---|---|---|---|

| Force F max. S3 25 % 10 sec 1) | 4 kN | 4 kN | 10 kN | 10 kN | 20 kN |

| Force F 100 % duty cycle 2) | 2.5 kN | 2.5 kN | 6 kN | 6 kN | 13 kN |

| Ram stroke | 100 mm | 100 mm | 150 mm | 150 mm | 150 mm |

| Speed max. | 200 mm/s | 200 mm/s | 200 mm/s | 200 mm/s | 100 mm/s |

| Projection | 129 mm | 129 mm | 129 mm | 129 mm | 160 mm |

| Ram bore | 10H7 | 10H7 | 20H7 | 20H7 | 20H7 |

1) Temporary peak load

2) Nominal force in continuous operation

Here you will find more technical data SCHMIDT® ElectricPress

Characteristics

- Simple parameterisation minimises commissioning time

- Quick changeover procedures due to retrievable operating profiles

- Increased flexibility

- Cost reduction of tools and their wear due to free, precise positioning.

- The low noise level provides a stress-free working environment.

- The design-related non-existent stick-slip effect optimises the assembly process compared to pneumatic drives, especially at low speeds.

Accessories ElectricPress

Throat extension block

Press frames and cast parts are electroless nickel-plated, steel components are black oxide finished, aluminum parts are anodized, precision steel surfaces are untreated.

Special fixture mounting plate

Special fixture tabletops, designed in conjunction with throat extension blocks, provide ram to table bore alignment when spacer is used.

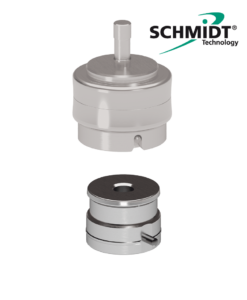

Upper tooling adapter

Adapter for tools with a diameter of 5 – 20 mm.

Quick Coupler for tools

consists of two parts: a rigid adapter and a base holder for mounting in the ram.

SCHMIDT® Press Base (PU)

Provides safe and vibration-free installation of all presses.

SCHMIDT® Slide Tables

Position longitudinally as well as transversely with high accuracy.

External handwheel

for intuitive setup of operating profiles

Safety concepts with EC type examination

Two-hand release

Simple triggering by means of two buttons to be pressed at the same time.

SCHMIDT® SmartGate

Patented safety with freely programmable safety gates for large presses, fast component feed, protection against interference as well as against parts flying out.

Light Curtain

In the event of unauthorized interference, the pressing process stops automatically.

SCHMIDT Presses product catalog

Find out everything about the various functions of our presses.

download PDF