SCHMIDT® PneumaticPress

Maximum pressing force from 1.6 kN to 60 kN

The SCHMIDT® PneumaticPress range builds on a modular concept and can generate up to 60 kN. They are ideally suited for joining, assembly and forming applications.

With the addition of the SCHMIDT® PressControl 75 or 700 and the optional process monitoring, these presses become EC type-approved, CE-conformed workstations. Therefore these press systems can be used in either single cycle or automatic mode.

SCHMIDT® PneumaticPress direct-acting

Constant force curve over the entire stroke; 1.6 to 43 kN

SCHMIDT® PneumaticPress Toggle Press

Maximum force at the end of the stroke; up to 60 kN

SCHMIDT® PneumaticPress with force/stroke monitoring

Monitored, constant force curve; 1.6 to 43 kN

Characteristics

- Optimal adaptation to individual requirements through modular design.

- Process optimisation through adjustable parameters (stroke, force, speed).

- Easy adaptation to different tool and workpiece heights through stepless stroke and height adjustment.

- Easy and exact positioning of tools through centric fitting bore and partly cross bore with fixing screw in the ground press table.

- Additional accident protection when using heavy tools through (optional) ram hold-up device according to DIN EN 13736.

- Optional end position sensing via cylinder switch as signal generator for peripheral processes.

- Low noise level (< 75 dBA)

- Double-acting, low-wear cylinders with low air consumption for the return stroke. The return stroke takes place via a cylinder chamber as standard.

- High flexibility thanks to short changeover times.

- Durable and precise thanks to maintenance-free, Teflon-coated bearings.

- Ground ram

- Precise, double ram bearings

Accessories PneumaticPress

Throat extension block

Press frames and cast parts are electroless nickel-plated, steel components are black oxide finished, aluminum parts are anodized, precision steel surfaces are untreated.

Upper tooling adapter

Adapter for tools with a diameter of 5 – 20 mm.

Nickel plated design

Press frames and cast parts are electroless nickel-plated, steel components are black oxide finished, aluminum parts are anodized, precision steel surfaces are untreated.

Special fixture mounting plate

Special fixture tabletops, designed in conjunction with throat extension blocks, provide ram to table bore alignment when spacer is used.

SCHMIDT® Press Base (PU)

Provides safe and vibration-free installation of all presses.

SCHMIDT® Slide Tables

Position longitudinally as well as transversely with high accuracy.

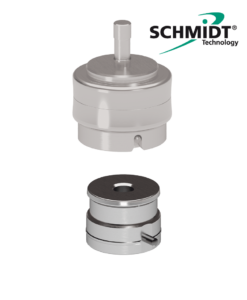

Quick Coupler for tools

consists of two parts: a rigid adapter and a base holder for mounting in the ram.

Safety concepts with EC type examination

Two-hand release

Simple triggering by means of two buttons to be pressed at the same time.

SCHMIDT® SmartGate

Patented safety with freely programmable safety gates for large presses, fast component feed, protection against interference as well as against parts flying out.

Light Curtain

In the event of unauthorized interference, the pressing process stops automatically

SCHMIDT® Presses product catalog

Find out everything about the various functions of our presses.

download PDF