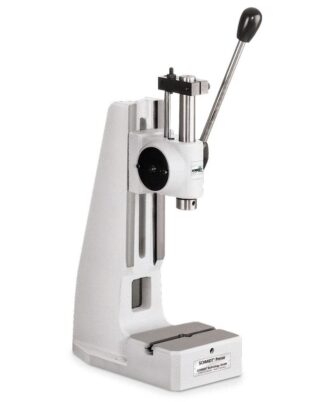

Features

- Linear force progression for No. 305 and No. 307

* High force at the end of stroke for No. 311

* Precise adjustment of the press depth via micrometer fine

adjustment

* Guides require little maintenance, have little wear and are

locked against rotation. This results in precise working

and a long service life

* Optimum guidance and clamping due to dovetail guide on the

press head

* Quick set-up

* Exact alignment of ram bore to the table within 0.05 mm

* Height adjustment using a crank

* Precision bores in ram and column base plate

Technical Data

| Press type | | | 305 | 307 | 311 |

|---|

| Nominal force | | kN | 0.4 | 4 | 12 |

| Force at the hand lever | | approx. N | 50 | 200 | 200 |

| Working stroke | A | mm | 42 5) | 54 5) | 50 1) |

| Throat depth | C | mm | 129 | 129 | 129 |

| Press head height | S | mm | 310 | 417 | 555 |

| Ram bore | Ø | mm | 6 H7 | 10 H7 | 10 H7 |

| Stroke fine adjustment | | mm | 0.02 | 0.02 | 0.02 |

| Stroke resolution | | mm | 0.005 | 0.005 | 0.005 |

| Angle of rotation/mm stroke | | | 3.3 ° | 4.8 ° | non linear |

| Resolution, process data acquisition | stroke

force | µm / inc

N / inc | 5

0.125 | 5

1.25 | 5

3.5 |

| Working height 5) | F | | | | |

| Frame No. 7-420 | | mm | 60 - 420 | 50 - 410 | 50 - 290 |

| Frame weight | | kg | 39 | 39 | 39 |

| Frame No. 7-600 3) O | | mm | 90-600 | 80-600 | 80-480 |

| Frame weight | | kg | 45 | 45 | 45 |

| Max. weight of the upper tool 4) | | kg | 0.6 | 1 | 1.3 |

| Weight | | approx. kg | 17 | 21 | 30 |

| Protection type | | | IP 54 | IP 54 | IP 54 |

| Accessories | | | 305 | 307 | |

|---|

| Stronger return spring | | | O | O | |

Speed control

| | | O | O | |

Throat depth frame 2) 3) (total

depth) 169, 209, 249 | | | O | O | |

| Frame overview | Press type | Frame height

M (mm) | Table size

W x D (mm) | Table bore

D (Ø mm) | Table height

K (mm) | Mounting Surface

B x L (mm) |

|---|

| Nr. 7-420 | 305, 307, 311 | 740 | 180 x 150 | 20H7 | 90 | 220 x 362 |

| Nr. 7-600 O | 305, 307, 311 | 960 | 180 x 280 | 20H7 | 110 | 220 x 465 – 505 6) |

Options

• Additional charge applies

1) Throat depth frame only available with frame No. 7-600

2) Increased throat and higher frame lead to smaler nominal forces for No. 311

3) The weight was determined with hand lever position 45° forward (guide)

4) Typical values; can vary ± 3 mm due to casting and production tolerances

5) Adjustable stroke with stop clamp (in the scope of delivery)

Other available Options:

* Nickel plated – cast parts are electroless nickel plated, steel components black oxide finished, aluminum anodized, precision steel surfaces are untreated

* Custom paint – press and column can be painted to customer's color specification

* Bores for adapting tooling – customer specific sizes can be supplied