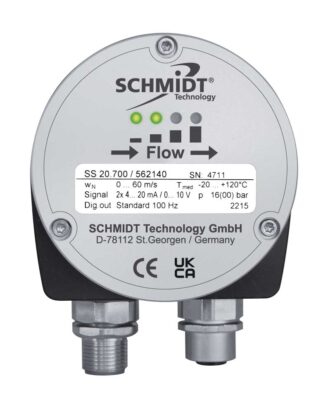

SCHMIDT® Flow Sensor SS 20.700

Flow rates of gases – an important measurement in industrial processes.

- "Heavy-Duty applications"

- Double-pin sensor head, sensor elements completely encapsulated in stainless steel

- For air and other gases in applications with harsh conditions (medium with aggressive components, contamination, high humidity)

- Flow and temperature signal

- Probe length of 250 or 600 mm

- Remote sensor (optional)

- Measuring ranges 0 … 10 m/s up to 0 … 220 m/s, special measuring range

- Special gas adjustment for different gases (optional)

- Pulse output

- Grease free / O2 applications / PWIS-free (optional)

- Pressure resistant up to 16 bar

- Temperature range up to +120 °C

- Module interface for expansion of sensor functions

The thermal SCHMIDT® Flow Sensor SS 20.700 is the perfect solution for extremely demanding industrial applications. It can be used for a diverse range of applications, such as compressed air monitoring, gas monitoring on process burners, consumption recording of gases and a great deal more.

Two specific versions „Oxygen O2 >21 %" and „Grease-free and Oxygen O2 >21 % (PWIS-free)" provide the required safety for applications with corresponding requirements.

The double-pin sensor head has been designed especially to meet the needs of so-called „heavy-duty applications“. Thanks to the sensor elements being completely encapsulated in stainless steel these are ideally suited for extremely demanding applications. The sensor is also resistant against aggressive media.

The SS 20.700 records flow velocity as well as media temperatures of up to 120 °C. It can be used in small tubes from DN40 upwards and can involve a sensor length of up to 600 mm to measure the volumetric flow rate in large channels and ducts. The sensor can be used in overpressure up to 16 bar.

This sensor is very easy to install: screw in the sensor using the compression fitting included, align the sensor in the gas flow and centrally in the pipe, connect it electrically – and job done!

The SS 20.700 operates without any moving parts and due to the measuring principle drifting or ageing do not play a role. This reduces the maintenance required for the sensor to an absolute minimum. Should cleaning nevertheless be necessary, it can be carried out very easily and in a variety of ways - simply the spirit of „heavy-duty“.

- Heavy-Duty applications

- Compressed air consumption measurement

- Inert gas flow measurement

- Flow rate control

- Compressor control

- Exhaust air monitoring

- Control of the combustion air at block heating plants and fuel cells

- Air mass flow measurement in burners and combustion engines

For calculations of measuring range with our flow calculator, please use settings for SS 20.600.

SCHMIDT Technology – Simply a question of better measurement

Specifications

| Technical data |

|---|

| Measuring quantity | Standard flow velocity wN based on standard conditions 1)

Temperature of medium TM |

| Measured medium | Air or nitrogen

Optional: Pure oxygen, argon, CO2, other gases on request |

| Measuring range wN | 0 … 10 / 20 / 60 / 90 / 140 / 220 m/s

Optional: Customised measuring ranges in steps of 1 m/s |

| Lower detection limit wN | 0.1 m/s |

| Measuring range TM | -20 … +120 °C |

| Measuring accuracy |

|---|

| Standard wN | ±(3 % of measured value + [0.4 % of fmr; min. 0.08 m/s]) 2) |

| Response time (t90) wN | 10 s (jump of wN from 0 to 5 m/s in air) |

| Temperature TM (wN > 2 m/s) | ±1 K (10 … 30 °C); ±2 K (remaining measuring range) |

| Operating temperature |

|---|

| Sensor probe | -20 … +120 °C |

| Electronics | -20 … +70 °C |

| Storage temperature | -20 … +85 °C |

| Material |

|---|

| Enclosure | Aluminium, anodised |

| Sensor tube | Stainless steel 1.4571 |

| Sensor head | Stainless steel 1.4404 |

| Sensor cable (of remote probe) | Jacket TPE, halogen free |

| Compression fitting | Stainless steel 1.4571, NBR (or FKM), depending on version |

| General data |

|---|

| Humidity | Measuring mode: Non-condensing (< 95 % RH) |

| Operating pressure (max.) | 16 bar (overpressure) |

| Display | 4 x Duo-LED (green/red/orange)

LED ring |

| Supply voltage | 24 V DC ± 20 % |

| Current consumption | Typ. 80 mA (without pulse outputs); max. 200 mA (excluding signal current of pulse output 2 [relay] and current consumption of extension module) |

Analog outputs

Type: Auto U / I) | wN, TM

0 … 10 V / 4 … 20 mA (switching of signal characteristic depends on RL)

-Voltage output (0 … 10 V): RL ≥ 550 Ω (short-circuit protected)

- Current output (4 … 20 mA): RL ≤ 500 Ω

- Change-over hysteresis: 50 Ω

- CL ≤ 10 nF |

| Pulse outputs: Signalization | Standard: Frequency f ~ wN

f = 0 … fmax

fmax = 100 Hz (option: fmax = 10 … 99 Hz)

Optional: Pulse quantity:

1 pulse/1 m3; 1 pulse/0.1 m3; 1 pulse/0.01 m3 (max. 100 pulses/s) |

| Pulse outputs: Technology | 1. Highside-driver (PNP, open collector) at protected supply voltage; not galvanically isolated)

Short-circuit protected (analog): 100 mA

High level: > supply voltage - 3 V

Leckage current: IOFF < 10 µA

2. Semiconductor relay; output galvanically isolated

Output voltage/current: Max. 30 V / 50 mA |

| Electrical connection | Main: Plug-in connector M12 (A-coded), male, 8-pin (shielded), screwed

Module interface: Plug-in connector M12 (A-coded), female, 5-pin (shielded), screwed |

| Maximum cable length | Voltage interface: 15 m

Current interface (pulse output): 100 m |

| Mounting position | Arbitrary (exception: Temperature element may never be placed “above” heater element) |

| Mounting tolerance | ±3° relative to flow direction (uni-directional) |

| Minimum immersion depth | DN40 |

| Protection type | Sensor probe: IP67; enclosure: IP65; electrical connectors: IP67 (with correctly attached cable) |

| Protection class | III (SELV or PELV) |

| Probe length | Compact version: 250/600 mm

Remote version: Probe 250/600 mm

Remote cable: 1 … 10 m (step: 1 m) |

| Weight | Approx. 500 g max. |

1) Standard conditions: TN = 20 °C and pN = 1,013.25 hPa

2) Related to adjustment reference; "fmr" = final measuring range

Subject to technical changes.

Accessories

Connection technology

| Description | Article-Number |

|---|

| Connecting cable, 8-pole, length 5 m, with coupler socket and open cable end | 524 921 |

| Connection cable 8-pole, length can be selected (2 … 100 m; 1 m steps), free of halogen, with cable end sleeves 1) | 524 942 |

| Coupler socket, 8-pole, with screw terminals, for cable ø 6 … 8 mm | 524 929 |

| Adapter cable M12, 8/4 pole, length 8 cm | 550 885 |

| Power supply unit: output 24 V / 1A DC, supply voltage 115/230 V AC (strip terminal) | 535 282 |

| Plug-in power supply 24 VDC / 1 A output, 100-240 VAC, 2 m cable length, M12-plug connector (screwed, only usable with "Adapter cable M12, 8/4-pole" 550885) | 571630 + 550885 |

Mounting and fixing technology

| Description | Article-Number |

|---|

| Compression fitting, stainless steel 1.4571, FKM, G½ | 535 092 |

| Compression fitting, stainless steel 1.4571, FKM, R½ | 539 190 |

| Welding sleeve, steel, G½ acc. to EN 10241, 5 pieces per pack | 524 916 |

| Welding sleeve, stainless steel 1.4571, G½ acc. to EN 10241, 2 pieces per pack | 524 882 |

| Assembly kit for pipe assembly, suitable for MD 10.010 / 10.015, including pipe clamps and collar for adjustment to pipe diameter | 531 394 |

| Probe ball value 1" inside thread, connection to flow sensor: ½" inside thread, incl. plug and chain | 530 940 |

| Probe ball value 1 ¼" inside thread, connection to flow sensor: ½" inside thread, incl. plug and chain | 530 941 |

| Probe ball value 1 ½" inside thread, connection to flow sensor: ½" inside thread, incl. plug and chain | 530 942 |

| Probe ball value 2" inside thread, connection to flow sensor: ½" inside thread, incl. plug and chain | 530 943 |

| Straight-run probe ball valve ¾" inside thread, with threaded adapter for ½" full-length screw connection | 532 355 |

| Welding socket, steel, outside thread ¾", 5 pieces per pack | 531 200 |

| Welding socket, stainless steel, outside thread ¾", 2 pieces per pack | 531 201 |

Measured value display

| Description | Article-Number |

|---|

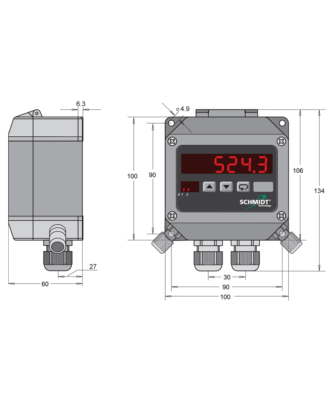

| LED display MD 10.010 in wall housing to show volume flow and flow velocity, 85 … 250 V AC and sensor power supply | 527 320 |

| LED display MD 10.010, similar to 527 320 but with 24 V DC voltage supply | 528 240 |

| LED display MD 10.015, similar to 527 320 but with additional sum function and second measuring input | 527 330 |

| LED display MD 10.015, similar to 527 330 but with 24 V DC voltage supply | 528 250 |

| Measuring value module MD 10.020, 7-Segment-Display, incl. 0.6 m connection cable to connect to module plug | 554 900 |

| SCHMIDT® Bluetooth® Module BT 10.010 | 560 500 |

| SCHMIDT® Sensor App (Android): free of charge download at "Service & Support" – Sensors | Download |

Miscellaneous

| Description | Article-Number |

|---|

| SCHMIDT® PC Programming Kit; Adapter (USB / M12, 5-pole), USB stick (Sensor App PC, driver; for PC, laptop, notebook; Windows) | 564 710 |

| SCHMIDT® Datalogger DL 10.010 | 569 300 |