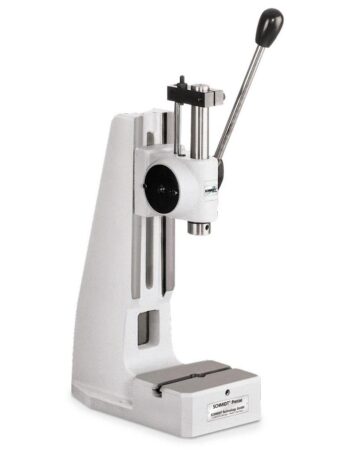

SCHMIDT® ManualPress Rack-and-Pinion Presses

Handhebelpressen von 1,6 kN bis 2,5 kN,

konstante Kraft über den gesamten Hub

Gerade bei Kleinserien ist ein Handarbeitsplatz mit mechanischen Pressen oftmals die wirtschaftlichste Lösung. Damit Sie Ihre Produktionsziele erreichen, haben wir die Handhebelpressen ständig weiterentwickelt. Sie benötigen einen langen Hub und linearen Kraftverlauf für Montageprozesse? Dann sind SCHMIDT® Zahnstangenpressen die richtige Wahl.

Merkmale

- Langer Hub

- Linearer Kraftverlauf

- Präzise Einstellung der Einpresstiefe über gehärteten Tiefenanschlag möglich

- Gehonte Stößelführung und geschliffene Stößel sorgen für lange Lebensdauer und präzise Führung

Zahnstangenpresse 5

Nennkraft 1,6 kN

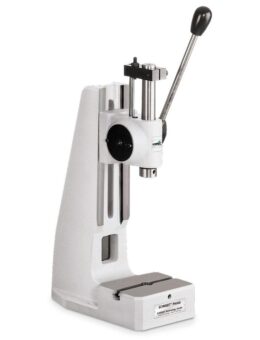

Zahnstangenpresse 3 und 6

Nennkraft 2,4 kN

Zahnstangenpresse 1 und 2

Nennkraft 2,5 kN

Optimierter Rückhubmechanismus für Zahnstangenpresssen Nr. 3 und 6 mit Hub 100 mm und 160 mm

Ein speziell für große Hübe optimiertes Federpaket führt zu einer deutlichen Verbesserung der Ergonomie. Zusätzlich sorgt der Einsatz des Ergohandles dafür, dass auch bei Drehwinkeln von > 360° kein Umsetzen der Hand nötig ist. Die auftretenden Kräfte am Handhebel werden durch ein Ausgleichsgewicht über den gesamten Hub konstant gehalten.

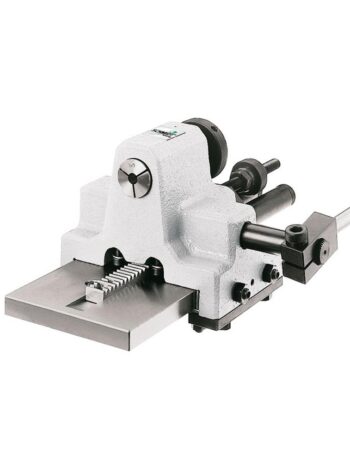

Presseneinheit

… mit geschliffener Flachführung bei Nr. 1 und Nr. 2 mit zweiseitig nachstellbaren, teflonbeschichteten Führungsleisten für spielfreie Führung

| Pressentyp | 5 | 5R* | 3 | 3R* | 6 | 6R* | 1 | 1R* | 2 | 2R* | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pressenschieber-Typ | 5 | 5R | 3 | 3R | 3 | 3R | 1 | 1R | 1 | 1R | ||

| Nennkraft | kN | 1,6 | 1,6 | 2,4 | 2,4 | 2,4 | 2,4 | 2,5 | 2,5 | 2,5 | 2,5 | |

| Arbeitshub Sonderhübe | A | mm | 40 | 40 | 70 / 160 | 70 / 100 | 70 / 160 | 70 / 100 | 80 100 | 80 100 | 80 100 | 80 100 |

| Ausladung | C | mm | 65 | 65 | 86 | 86 | 86 | 86 | 86 | 86 | 86 | 86 |

| Schieberhöhe | S | mm | 240 | 240 | 350 | 350 | 350 | 350 | 400 | 400 | 400 | 400 |

| Stößelbohrung | Ø | mm | 10H7 | 10H7 | 10H7 | 10H7 | 10H7 | 10H7 | ||||

| Spannzange (Stand. Ø 10) | Ø | mm | 1 – 17 | 1 – 17 | 1 – 17 | 1 – 17 | ||||||

| Handhebel links | O | O | O, außer 160 | O, außer 100 | O, außer 160 | O, außer 100 | • | • | • | • | ||

| Drehwinkel/mm Hub | 4,1° | 4,1° | 3.2° | 3.2° | 3.2° | 3.2° | 2.2° | 2.2° | 2.2° | 2.2° | ||

| Max. Gewicht Oberwerkzeug 3) | kg | 1,5 | 1 | 2,5 | 2 | 2,5 | 2 | 1 | 1 | 1 | 1 | |

| Rückhubsperre 1) | ||||||||||||

| Mindestarbeitshub* | mm | 17 | 18 | 18 | 26 | 26 | ||||||

| Sperrstellung 1 | mm vor UT | 11,5 | 13 | 13 | 19,5 | 19,5 | ||||||

| Sperrstellung 2 | mm vor UT | 3,5 | 4,5 | 4,5 | 7 | 7 | ||||||

| Ausrastgenauigkeit | mm | 0,06 | 0,07 | 0,07 | 0,08 | 0,08 | ||||||

| Arbeitshöhe 4) | F | |||||||||||

| Ständer Nr. 13 | mm | 55 – 200 | 55 – 200 | |||||||||

| Ständer Nr. 3 | mm | 75 – 220 | 75-220 | 120 – 260 | 120 – 260 | |||||||

| Ständer Nr. 2 | mm | 100 – 355 | 100 – 355 | 145-360 | 145-360 | |||||||

| Ständer Nr. 2-600 | mm | 200 – 600 | 200 – 600 | 200 – 600 | 200 – 600 | 245 – 650 | 245 – 650 | 245 – 650 | 245 – 650 | |||

| Ständer Nr. 2-1000 | mm | 300 – 1030 | 300 – 1030 | 300 – 1030 | 300 – 1030 | 380 – 1080 | 380 – 1080 | 380 – 1080 | 380 – 1080 | |||

| Gewicht | ca. kg | 11 | 11 | 22 | 22 | 30 | 30 | 23 | 23 | 31 | 31 |

| Zubehör | 5 | 5R* | 3 | 3R* | 6 | 6R* | 1 | 1R* | 2 | 2R* |

|---|---|---|---|---|---|---|---|---|---|---|

| Mechanischer Zähler | O | O | O | O | O | O | O | O | O | O |

| Ausladungsadaption (Gesamtausladung) 111 mm, 131 mm, 160 mm, 200 mm | O | O | O | O | O | O | O | O | ||

| Zusätzliche Tischplatte passend zur Ausladungsadaption | O | O | O | O | O | O | O | O | ||

| Mikrometeranschlag | O | O | O | O | O | O |

| Ständerübersicht | Pressentyp | Ständerhöhe M (mm) | Tischgröße B x T (mm) | Tischbohrung D (Ø mm) | Tischhöhe K (mm) | Stellfläche B x L (mm) |

|---|---|---|---|---|---|---|

| Nr. 13 | 5 | 330 | 110 x 80 | 20H7 | 46 | 110 x 185 |

| Nr. 3 | 3, 1 | 400 | 150 x 110 | 20H7 | 60 | 150 x 260 |

| Nr. 2 | 6, 2 | 536 | 185 x 110 | 20H7 | 60 | 185 x 280 |

| Nr. 2-600 | 3, 6, 1, 2 | 810 | 200 x 160 | 20H7 | 98 | 200 x 290 |

| Nr. 2-1000 | 3, 6, 1, 2 | 1250 | 200 x 160 | 20H7 | 98 | 200 x 290 |

Optionen

• Serie ohne Aufpreis o Variante mit Aufpreis

1) Anpassung der Sperrstellung auf Anfrage möglich

2) Gewicht wurde ermittelt in Handhebelstellung 45° nach vorne (Richtwerte) bei Standardhub (nicht Sonderhub)

3) Typische Werte; können auf Grund von Guss- und Fertigungstoleranzen ± 3 mm abweichen

Sonderausführungen

- Vernickelte Ausführung gegen Aufpreis, Pressenständer, Gussteile und Tischplatte chemisch vernickelt, Stahlteile brüniert,

- Aluminiumteile eloxiert, geschliffene Bauteile blank

- Sonderlackierung RAL-Farben

- Sonder-Tischbohrungen und Sonder-Stößelbohrungen auf Anfrage

SCHMIDT Presses product catalog

Find out everything about the various functions of our presses.

download PDF